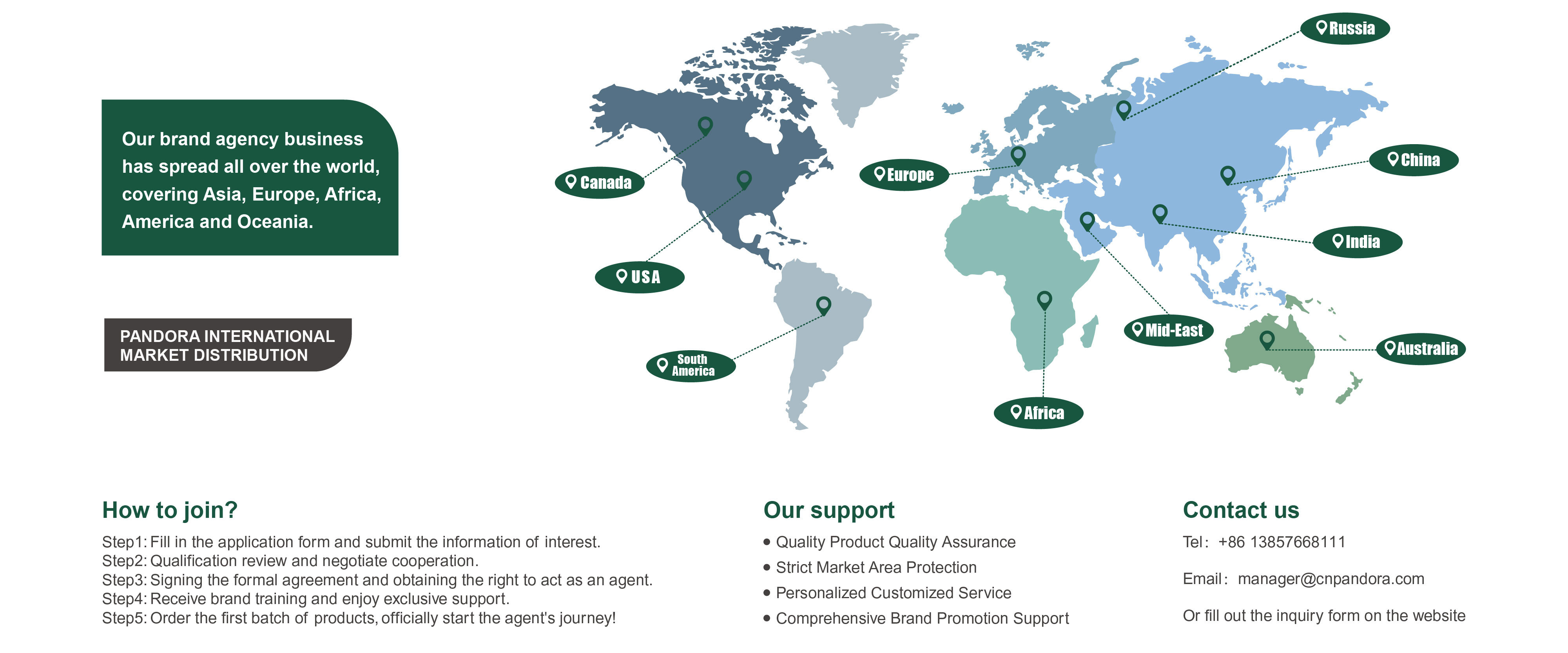

Brand Agency

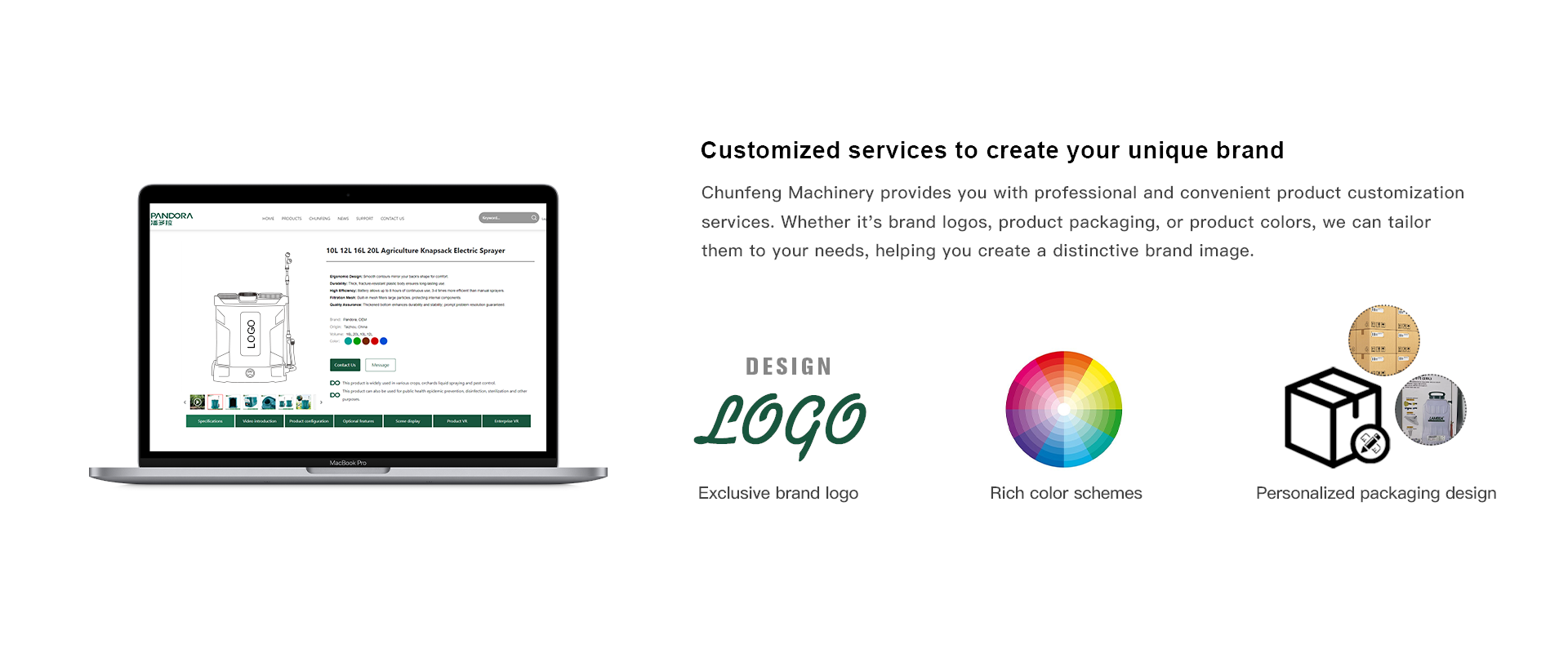

Customization

Questions and Answers

Common faults of the sprayer such as spray can not spray, can not spray evenly and continuously, difficult to trigger the rocker, leakage, inflexible switch, poor atomization quality, no pressure in the air chamber, etc., need to be checked and repaired according to the cause of the fault. In addition to repairing the sprayer, the use of the sprayer should also pay attention to maintenance...

1.

Spray no fog and dripping. The reason is a casing screen clogging, the second is the nozzle in the diagonal hole clogging. Remove the nozzle to clear the blockage.

2.

Spray water and gas sprayed out at the same time. The reason may be the barrel of the liquid delivery tube welding seam de-welding, or liquid delivery tube is corroded by the liquid, this time we can be welded or replaced with a new tube.

3.

The spray mist is scattered, not conical. May be due to the shape of the nozzle hole is not correct or blocked by dirt, resulting in poor atomization. At this time we can unscrew the nozzle cap to adjust, while clearing the nozzle hole dirt.

Technical Services

TAIZHOU CITY CHUNFENG MACHINERY CO., LTD.

Address: No.88, Binfeng Road, Sanjia Street, Binhai New District, Taizhou City, Zhejiang Province, China

Global Export

General Manager Cai: +86 13857668111

Manager Jiao: +86 13906587617

Mailbox: manager@cnpandora.com

Domestic Market

Sprayer: Manager Ruan +86 15258580998

Drip Irrigation Tape: Manager Zhang +86 18258666877

General Manager Cai (Export)

Manager Jiao (Export)

Manager Ruan (Domestic Sales)

Manager Zhang (Domestic Sales)

%E7%AC%AC%E4%B8%80%EF%BC%8C%E6%9C%80%EF%BC%8C%E4%BC%98%E7%A7%80%EF%BC%8C%E5%A2%9E%E5%BC%BA%EF%BC%8C%E4%B8%80%E6%B5%81%EF%BC%8C%E5%8D%93%E8%B6%8A%EF%BC%8C%E9%A2%86%E5%85%88%EF%BC%8C%E5%85%88%E8%BF%9B%EF%BC%8C%E5%BC%95%E9%A2%86

Sorry,当前栏目暂无内容!

您可以查看其他栏目或返回 首页

Sorry,The current column has no content!

You can view other columns or return Home